Killjoy environmentalists would have us stop shopping to save the planet. What a relief, then, to find a website, shopmodify.com, that teaches us how to shop and save the planet at the same time. I especially like their green shopping tips for Spring: “buy a hot eco-friendly outfit, or choose not to take an ATM slip”. The ATM-slip idea is too profound for me to grasp right now, so my thoughts turn to t-shirts: They’re made of natural materials so you can’t have too many of them, right?

Well, yes you can. According to Kate Fletcher’s fascinating book Sustainable Fashion and Textiles the cultivation of just one kilo of cotton draws on as much as 8,000 litres of water- much of which ends up saturated with a shedload of pesticides. Waste is also a problem: UK citizens alone generate nearly 40kg each of textile waste every year. Only a quarter of these kilos are reclaimed; the rest go to landfill. Transport costs are also a big issue: the average T-shirt, I learn from the book, travels the equivalent distance of once round the globe during its production.

So now we have to watch fabric miles as well as food miles.

Global food and textile systems are inter-linked to a surprising degree. For example, a lot of people buy t-shirts at Primark, a discount chain famous for ultra-low prices and celebrity customers. Usually described as an Irish retailer (it was started by a family called Ryan – but not the same Ryan who runs the discount airline) Primark is in fact owned by Associated British Foods (ABF), a multinational food, ingredients and retail group.

ABF, to its credit, publishes data about its activities on the CDP website. Here, among the largest repository of corporate greenhouse gas emissions data in the world, ABF states that it provides “wholesome and nutritious foods, food ingredients, animal feedstuffs, and quality affordable clothing…and (makes) sure that these are produced efficiently and to a high quality”.

The words “efficiently and to a high quality” may be true, but they do not mean “sustainably” – either in production terms alone, or in their impact on the bigger textile system. As Fletcher points out, cheap cotton in Primark takes just as long to grow, and uses just as many resources per unit of weight, as the cotton used in a $200 t-shirt. Also, the price of cheap virgin fibres in Primark is so low that it has become uneconomic for anyone to collect, sort, distribute and resell the clothes we discard. In discount systems like Primark’s, over 90 per cent of resources employed become waste within three months of purchase.

But ABF/Primark’s global system is only part of the story. Even if Primark were to use only bamboo and soyabean fibres, grow 100% organically, and produce only locally, its t-shirts woud still not be sustainable because of what happens when we get a garment home. The average piece of clothing is washed and dried 20 times in its life: 82 percent of its lifetime energy use, and over half the solid waste, emissions to air, and water effluents it generates, occur during laundering.

Among many quirks in the fashion and textile system is the fact that a $200 t-shirt has a heavier enviromental impact than a Primark one – because it gets washed, rather than chucked away. Buying a “hot eco-outfit”, it turns out, is easier said than done.

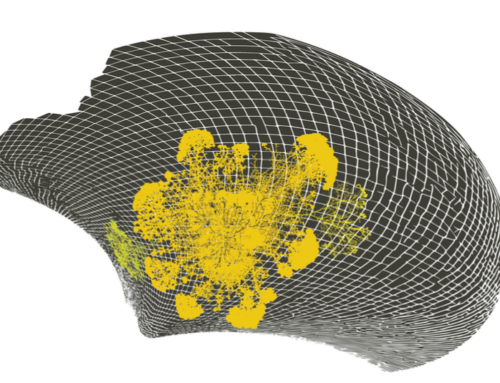

One of the many strengths of Fletcher’s book is the clarity of its analysis of the textile system as a whole. For all the air-head antics of celebrity designers, fashion and textiles is one of the most complex in today’s massively inter-linked economy. It involves raw materials, chemicals, emissions, recyclability, and biodegradability – at each of many steps in the chain. Each step is itself a complex process: Growing plants; extracting yarns from them; spinning, weaving and knitting; bleaching; dyeing; fabric finishing; printing, trimming, packaging – and so on.

A product policy based only on “reuse, and recycle”, warns Fletcher, might optimise one part of this complex system – but not the whole.

Technical scenarios also suffer from too-limited horizons. One of the more intriguing prospects mentioned in the book is that of self-cleaning, no-wash textiles. But even if no hidden energy or pollution costs in their manuafacture emerge (a big ‘if’) other re-bound effects, that are impossible to predict, are inevitable.

The same goes for the idea of biodegradable textiles designed to be fully absorbed by the earth; we simply can’t know for certain what the consequences of “green” landfill on such a scale might be.

The answer is not exclude these, or any other, potential solutions. But it would also be a mistake to focus on particular sub-routines in isolation. What’s needed is a simple but radical definition of where we need to be – a zero-waste, zero-emissions system. This would give all actors in the supply chain – farmers, brokers, chemists, designers, producers, retailers, and consumers – something to work towards, together.